Industrial magnets by norelem

norelem magnets are available with different magnetic cores and housings. Magnetic cores are made of permanent magnet materials such as AlNiCo (aluminium, nickel and cobalt), NdFeB N35 (neodymium), hard ferrite or SmCo (samarium-cobalt).

Due to the respective technical design of norelem magnets, they differ in their magnetic face, magnetic force/strength and therefore in their use in industry.

Example: Design of a norelem industrial magnet using a retaining magnet

The magnetic cores differ, for example, in terms of heat resistance, demagnetisation and magnetic force/strength. Coatings made of steel, stainless steel, aluminium or rubber protect the magnetic core and also support magnetic function.

The shape of magnets plays another important role here as depending on the application and area of use in industry, different shapes are required, such as flat, round, square, with or without hole, U-shaped or bar.

Magnets also differ in their system. norelem magnets can be purchased both in a shielded system in which only certain areas exert a magnetic force and in an unshielded system in which the entire surface has a magnetic effect.

Properties of norelem industrial magnets

The property of the magnetic core is aimed at the strength (magnetic force) of the magnet. That is why norelem magnets with a magnetic core made of neodymium are very strong industrial magnets unlike norelem magnets with a magnetic core made of hard ferrite. However, these norelem magnets have a lower heat resistance than norelem magnets made of hard ferrite or aluminium, nickel and cobalt.

Magnets: Types and shapes

Raw magnets

norelem raw magnets can be used universally and be fitted by pressing in, screwing in or gluing in. Raw magnets are always unshielded and therefore not magnetic systems. All surfaces of raw magnets therefore exert magnetic force. Raw magnets are divided into disc magnets, disc magnets with a hole, block magnets and bar magnets.

The disc magnet in the class of raw magnets is available in the norelem online shop both with a hole (disc magnet can also be screwed in and thus fixed firmly) as well as without a hole . Disc magnets are made of NdFeB N35 (neodymium) and have a galvanised surface.

norelem bar magnets are made of AlNiCo (aluminium, nickel and cobalt) and feature high heat resistance (temperature range up to a max. of 450 °C). The bar magnets are available in different lengths and diameters depending on requirements.

Block magnets differ from disc magnets only in their shape. The flat shape offers optimum conditions for easy and handy use of the block magnets in industry.

Round magnets made of aluminium, nickel and cobalt

These magnets have a core made of permanently magnetic material (AlNiCo) and a housing made of steel. The magnetic core is separated from the housing by a non-magnetic material, creating a shielded system. Fastening options are press-fitting, shrink-fitting or gluing.

The magnets are available in a round shape as deep pots with pin, with and without fitting tolerance. All round magnets are heat-resistant (up to a max. of 450°C), have a high magnetic force and come in different versions.

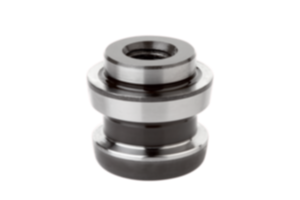

Round magnets made from neodymium and samarium-cobalt (SmCo)

In this case a distinction is to be made between deep pot magnets with a magnetic core made of NdFeB (neodymium) and SmCo (samarium-cobalt). The magnetic core is protected by a brass housing with a smooth surface, resulting in a shielded system.

SmCo magnets are particularly suitable for direct use in spot welding machines as no demagnetisation occurs.

Permanent magnets for workholding with fine pole division

norelem workholding magnets consist of a permanent magnetic system with fine pole divisions effective on two or three faces. The finer the pole division, the thinner the clamped steel workpieces can be. The magnetic lifespan of workholding magnets under conditions prevailing in industrial machining is unlimited.

Magnets (shallow pots)

The magnetic core of shallow pot magnets is moulded or pressed into a housing. There is a non-magnetic barrier between magnet and housing. For that reason shallow pot magnets are shielded systems.

Shallow pot magnets are available with a magnetic core made of hard ferrite, samarium-cobalt (SmCo), or neodymium (NdFeB). The difference lies in the magnetic force of shallow pot magnets. Shallow pot magnets with SmCo cores have between three and five times the magnetic force of AlNiCo or hard ferrite shallow pot magnets. Shallow pot magnets have a housing made of steel or stainless steel.

Shallow pot magnets are available from the norelem online shop in different versions with and without thread, with internal thread, hook, counterbore and countersink.

Magnets (shallow pots) with protective rubber jacket

One major advantage of shallow pot magnets with protective rubber jacket (TPE or synthetic rubber) is the protection of the magnetic core and sensitive surfaces of the magnets. The protective rubber jacket of shallow pot magnets increases the coefficient of friction so that a high lateral static friction force can be achieved.

Shallow pot magnets with protective rubber jacket are available with female thread, rectangular (optimum hold on thin sheets with sensitive surfaces), with tapped pin, threaded pin and hole .

The shallow pot magnet range by norelem includes protective rubber caps for shallow pot magnets . The protective rubber caps are slipped over the magnetic surface of shallow pot magnets. The shearing force with which the magnet can be displaced is doubled and reaches almost the original holding force of the magnet. The protective rubber caps fit all shallow pot magnets with a diameter of 50 mm, 63 mm and 80 mm.

Deep pot magnets & button magnets

Deep pot magnets are hard magnets with an aluminium housing and steel coating. Deep pot magnets have a high heat resistance. The housing of deep pot magnets is painted red. Deep pot magnets have a shielded system and are used for holding, lifting and installation in fixtures. Where space is limited in fixtures, shallow pot magnets can be used.

Button magnets have a split magnetic face with through hole for fastening. Button magnets are mainly used in laboratories, inspection rooms and for holding metal objects in place.

Horseshoe magnets

The red-painted horseshoe magnets made of the permanently magnetic material AlNiCo have a high magnetic force, an unshielded system and are supplied with a galvanised protective plate. Horseshoe magnets are used for holding, sorting and lifting.

Retaining magnets

Retaining magnets, the magnetic core of which is made of hard ferrite, are often used on notice boards, whiteboards and magnetic boards. The housing is made of plastic.

Accessories

In addition to magnets, the norelem product range also includes matching accessories.

Chromed magnetic pick-ups with flexible brass tube and black plastic grip are mainly used for removing or searching for steel parts in inaccessible places.

Permanently magnetic bases with on/off switch, a black surface and high magnetic force are used in fixtures as retaining magnets, gauge stands, pull-off diamonds, etc.

Magnetic clamping balls made of aluminium are used to hold components in optimum working position during, for example, polishing, assembly and laser welding. Swivel angles of up to 90° can be set, depending on the workpiece geometry and weight. The magnetic ball can be turned on and off using the T-grip hex key provided.