Compression springs/helical compression springs from norelem

The compression springs or helical springs in the norelem range are made from of a rectangular profile, chrome-silicon steel wire. The springs are wound in such a way that they respond to pressure.

The helical compression springs in the norelem range have standard diameters of 10 - 25 mm and lengths of 25 - 305 mm Springs with different load ratings that have the same diameter and length enable easy exchanges when a different load grade is required. In addition, the special profile of the compression springs permits high alternating and continuous loads and can be used at operating temperatures of up to 230 °C.

Application areas of helical compression springs in industry

Due to their versatile application, helical compression springs are used in tool, machine and fixture construction, among other things.

Application examples for compression springs

Wherever machine parts need to be moved, norelem compression springs/helical springs are used. The norelem springs are also used for opening or closing relay contacts. The helical springs are used as a frictional connection for e.g. door checks or friction clutches.

Service life of compression springs

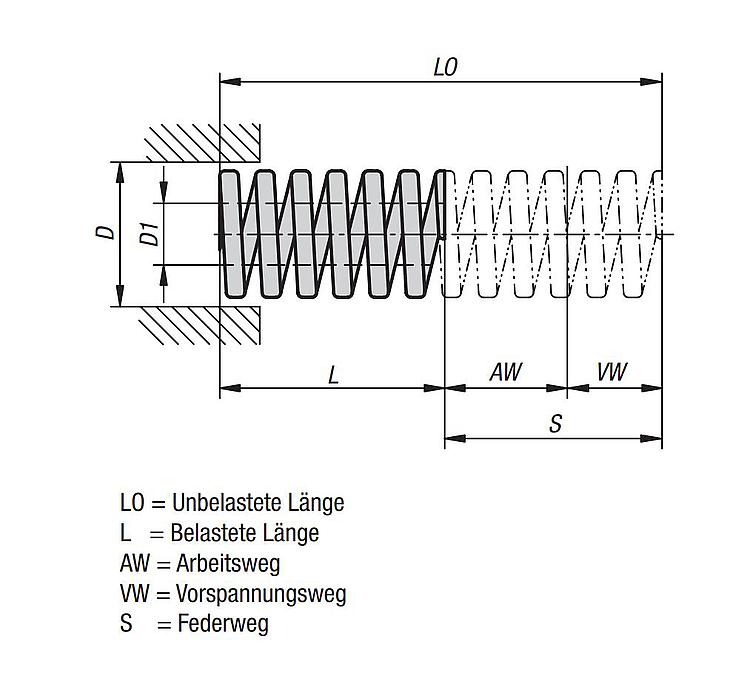

The service life of the compression springs can be determined by splitting the entire spring travel into working travel and pre-load travel. The smaller the difference between the spring travel and the unloaded length of the spring, the longer the expected service life. Therefore, to maximise service life, the pre-load of the helical compression springs should be as high as possible and the working travel as short as necessary.

Spring travel

The spring travel (S) is the distance by which the compression spring is compressed after force is applied. The spring travel is the sum of the working travel and the pre-load travel ( calculation example: difference between L0 and L).

Pre-load travel

To ensure that the spring does not cause any noise once installed and is not loose in the mounting element, the spring should always be designed with pre-load (VW) (calculation: length L1 = length L0).

Working travel

The working travel is the travel of the spring when the spring has been installed with no pre-load.

Unloaded length

The length of the spring when installed, without a force acting on it. To extend the service life of the compression springs, they are also heat treated, abrasive blasted and preloaded to solid height during production.

Solid height

The solid height is the length of the spring when all the coils are in contact with the adjacent coils.

norelem compression spring types

The helical compression springs are available in four load ratings identified by different colour groups. The identical lengths and diameters of the springs enable interchangeability between the different load ratings. The spring type used depends on the requirements (what force is needed). The norelem range includes the following load ratings, strengths and spring types: The lengths, diameters, force and colour of the springs comply with the ISO 10243 standard. This standard specifies, among other things, the installation dimensions and tolerances of compression springs with a rectangular cross-section. As a manufacturer of compression springs, norelem offers the appropriate CAD data for the compression springs as a download or on a USB stick, as with all products in the full range or online shop. The application area in tool, machine and fixture construction is identical for all compression springs.