norelem moves – 26000

Product group 26000 from norelem consists of seven categories:

- Compression springs

- Elastomer buffers

- Rubber buffers

- Damping plates

- Profile dampers

- Gas springs

- Shock absorbers

Compression springs

The compression springs from norelem consist of a rectangular profile wire made of chrome silicon steel. They are also known as helical compression springs and are wound in such a way that the springs respond to pressure.

The compression springs are available in diameters of 10 to 25 mm and lengths of 25 to 305 mm. They can be used up to an operating temperature of 230°C. The special profile of the norelem compression springs enables an enormous alternating or permanent load.

There are four different compression springs in the range. The individual helical compression springs are divided into four colour groups for this purpose. The spring type is determined by the required force.

Green – is used for light loads

Blue – with medium load

Red – with heavy load and

Yellow – with particularly heavy load

The characteristics of the compression spring, such as the length, diameter, force and colour of the springs, all comply with the ISO 10243 standard. Among other things, this standard specifies the installation dimensions and tolerances of compression springs with a rectangular cross-section.

Each compression spring, from green to yellow, is available in the same lengths and diameters. This enables easy replacement, even if a different load level is required.

In addition to their use in toolmaking and machine construction, compression springs are also used in fixture construction. The versatility of the compression springs makes them an everyday item in industry. Basically, however, compression springs are used when a machine part needs to be moved.

Elastomer buffers

Elastomer buffers insulate and dampen airborne and structure-borne noise. The springs are therefore used to cushion moving masses and serve to isolate vibration exciters. They are characterised by their high mechanical load rating and long service life. Even with a hard setting, the elastomer buffer has a high degree of impact resilience.

As they are maintenance-free, elastomer buffers are one thing above all – economical!

In addition to the advantages mentioned above, it is important to mention in particular that the elastomer buffer does not break even in the event of major overloading. This helps protect people and machines.

Resistance to oils and greases rounds off the profile of the elastomer buffer. All quality requirements for elastomer buffers from norelem are based on the DIN ISO 10069-1 standard.

The norelem range includes the following versions of elastomer buffers:

Rubber buffers

Rubber buffers belong to the product family of buffer elements. They are among the most widely used design and standard elements for elastic mountings in the industry. This is why rubber buffers are used in a wide variety of applications. The buffers dampen and cushion vibrations on the machine and absorb kinetic energy.

The rubber buffers from norelem are characterised by their excellent shock absorption and cushioning as well as their robustness.

These properties are particularly advantageous for recurring impact force and acceleration with an end plate.

The following needs to be taken into account when selecting a suitable rubber buffer:

The rubber buffers are less resilient under shear loads than under compressive loads.

The rubber buffers are available in various degrees of hardness in the norelem range. Reliable cushioning and durability are guaranteed by the combination of natural rubber, steel and stainless steel.

Whether rubber buffers with an internal or external thread, norelem offers rubber buffers to suit your installation requirements. norelem differentiates between the various rubber buffers according to "rubber buffer types". This indicates the application possibilities of the rubber buffer with its thread in the machine or industry.

The following rubber buffers are included in the range:

- The rubber buffers in the Type A product group have an external thread on both sides.

- Type B product group have an internal thread and an opposite external thread.

- The rubber buffers in the Type C product group have an internal thread at both ends.

- The rubber buffer in the Type D product group has an external thread and a natural rubber overlay on the visible surface as an end stop to limit the spring deflection for moving bodies.

- The rubber buffers in the Type E product group differs from Type D only in terms of the internal thread.

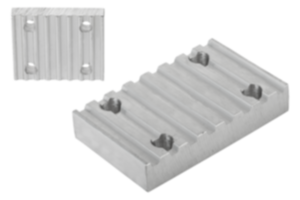

Damping plates

Damping plates are used to reduce individual impact loads. In other words, in places where vibration begins and needs to be cushioned as quickly as possible.

The damping panels from norelem are made of cellular polyetherurethane. The material enables the damping plates to withstand impact loads and effectively absorb continuous loads.

The plates are installed by simply gluing them together. The damping surface can therefore be increased by lining up damping plates. If the area is still too large, the damping plates can be subsequently customised.

The density of the damping plates is differentiated by colour. The individual colours therefore have the following meaning:

- Red = soft (density 165 kg/m³)

- Green = medium (density 460 kg/m³)

- Bordeaux = hard (density 1000 kg/m³)

Profile dampers

Profile dampers from norelem are a type of vibration damper used to reduce vibrations and noise in machines and systems. They are mounted on the connecting points between machine parts or system components to reduce the transmission of vibrations and noise. These profile dampers are made of an elastic material that absorbs the energy of the vibration and thus prevents it from being transmitted to other parts of the system.

Profile dampers are an important element in the machine construction industry, as they extend the service life of machines through absorption.

Profile dampers from norelem are specially developed to meet the requirements of the machine construction industry. They are made of high-quality materials and offer a long service life as well as high resistance to vibrations and oscillations. They are also easy to install and can be adapted to different types of machine components.

The following versions are included in the range:

Gas springs

Gas springs control, brake and move masses without great effort. They are used in construction technology for damped movements (opening, closing and adjusting) of hatches, lids or hoods. The high corrosion resistance and low maintenance requirements make gas springs a very convenient solution for designers. Gas springs are used in areas such as machine, plant and fixture construction. They can also be found in the furniture industry, in household and sports equipment and in the automobile industry.

Gas springs from norelem are filled with nitrogen and oil and can withstand operating temperatures from -20°C to +80°C.

The stainless steel version of the gas springs contains oil that fulfils FDA regulation 21 CFR 178.3570. This means that stainless steel gas springs can also be used in the food processing industry.

Shock absorbers

The shock absorbers brake moving bodies quickly and gently. So they are suitable for use in handling devices, turn & swivel units, linear cylinders, and many other industrial applications, especially automation. Shock absorbers are mainly used in machines and systems to dampen movements and reduce vibrations. They can also be used to extend the service life of machines and systems by reducing the load on components.

Shock absorbers work according to the principle of physics that relates to the conservation of energy. They absorb the energy from bodies and convert kinetic energy into heat through friction with the internal oil flow. The generated heat energy is transferred to the cylinder body of the shock absorber, from where it passes out into the environment.

The shock absorbers from norelem are available in different sizes and versions and can be used for a wide range of applications.

norelem offers shock absorbers made of steel or stainless steel, which are also suitable for temperature ranges between -50°C and +120°C.