Ball-end thrust screws from norelem

Precise transmission of force and adaptability to uneven surfaces

Selecting the correct ball-end thrust screw from norelem

norelem as your supplier of ball-end thrust screws

Ball-end thrust screws from norelem

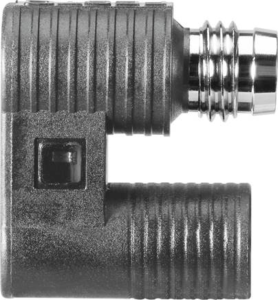

Thrust screws and ball-end thrust screws from norelem are versatile standard parts. They are used in numerous industrial applications for the secure fixation and adjustment of workpieces. Thrust screws enable precise clamping operations. Ball-end thrust screws with their movable balls on the other hand, exert even pressure on sensitive or uneven surfaces.

Ball-end thrust screws are equipped with a freely rotating ball at one end. These screws are available with or without heads, depending on the version. They are used to apply pressure evenly to a surface without damaging it. The ball ensures that the pressure is distributed flexibly and that there is no punctual pressure. This is particularly advantageous for sensitive materials or uneven surfaces.

Ball-end thrust screws are used in clamping fixtures, machine construction and workpiece fixtures to securely hold components in place or to prevent movement. They are ideal for applications in which sensitive materials or uneven surfaces cannot tolerate punctual pressure. The screws are also suitable for applications where flexible adjustment is required.

A ball-end thrust screw consists of the following main components:

- Screw body: The cylindrical or tapered part of the item that is threaded. This is so that that product ca be screwed into a component or a fixture.

- Ball: At one end of the threaded body is a freely rotatable ball that transfers the pressure to the workpiece or surface. The ball is usually made from hardened steel or stainless steel.

- Ball holder: A special recess or spring mechanism in the screw body that holds the ball in place while permitting movement. The ball mount ensures that the ball can adapt to different surfaces without transferring pressure directly to the material.

Sometimes additional elements such as a spring or a circlip may be added. These components hold the ball in position or cushion the pressure. The screws are available from norelem with or without a head, depending on the type.

Are you considering using a wing grip or T-grip, but are still unsure which variant is best suited to your system?

No problem! We provide you with free CAD data for all our grip types. Download the files and test which of these standard parts can be optimally integrated into your application.

Precise transmission of force and adaptability to uneven surfaces

Ball-end thrust screws offer numerous advantages that make them an indispensable component in many applications.

Uniform force transmission

The ball in the thrust screw enables an even and consistent pressure distribution, which permits precise forces to be applied to the workpiece.

Punctual force transmission

The spherical tip on the ball-end thrust screw applies force precisely to a specific point. This is particularly important in applications with high precision requirements.

Damage prevention

The contact via the ball ensures that the pressure is applied with pinpoint accuracy. This minimises the risk of surface damage or deformation of the workpiece and ensures that the clamping process is gentle on the material.

Reduced wear and damage

The punctual load and gentle fixation minimise wear on both the ball-end thrust screw itself and the workpiece. This ensures a longer service life for the component.

Adaptability to uneven surfaces

The movable ball of the ball-end thrust screw allows it to adapt to irregular or inclined surfaces, ensuring secure and gentle fixation.

Easy adjustment

Their design enables quick and easy fine adjustment, which facilitates handling in precision workflows.

High stability even under dynamic loads

Ball-end thrust screws offer high stability, even under changing or dynamic loads. This makes them ideal for demanding industrial applications.

Flexible application possibilities

Ball-end thrust screws can be used at different angles without affecting the transmission of force or the contact quality. This makes them highly versatile – ideal for clamping, locking or supporting, even on non-parallel surfaces.

Many variants

The products are available in different versions, with various mounting and contact surfaces, such as serrated, flat, rounded or pointed. In addition, the required diameter can be selected using the filter option, enabling precise customisation to individual requirements.

These properties make ball-end thrust screws indispensable, particularly in precision engineering, machine construction and automation technology.

Selecting the correct ball-end thrust screw from norelem

Selecting the appropriate ball-end thrust screw from norelem is crucial for precise and reliable positioning. When selecting ball-end thrust screws, several criteria play an important role. To ensure that the standard parts meet the requirements of the specific application, you should consider the following.

First of all, the screw material should be taken into account. Depending on the application, different materials such as steel, stainless steel or other alloys are better suited to withstand corrosion, wear and mechanical stresses.

The surface finish is also an important aspect that affects the lifespan and functionality of the ball-end thrust screw. The coating or surface treatment protects against external influences such as moisture or chemicals.

The size and thread of the ball-end thrust screws must also be carefully selected. That way, the screw can guarantee an optimal fit and function in the respective construction.

Another important factor is the load capacity, this determines how much pressure or load the screw can bear. This depends on the choice of material as well as on the design of the screw.

Finally, economic aspects such as availability and price should also be taken into account in order to find the best balance between quality and costs.

All these factors must be considered in combination to select a ball-end thrust screw that is optimally matched to the specific requirements.

norelem as your supplier of ball-end thrust screws

norelem is your reliable partner for high-quality ball-end thrust screws. With our wide range and high availability, we offer tailor-made solutions for a wide variety of applications.

Our ball-end thrust screws are characterised by precision, durability and easy handling. They are designed to meet the highest mechanical requirements and to enable easy installation and maintenance. We also offer short delivery times and comprehensive technical advice.

Whether you are looking for standard applications or individual solutions, we can always provide you with the appropriate product.

We place great emphasis on the highest manufacturing standards and ensure that every product meets our strict requirements through continuous quality control. You can also benefit from our expertise and extensive know-how in the field of mechanical components.

norelem offers you not only products, but also comprehensive service – from technical advice to flexible and fast delivery. You can rely on norelem as your supplier for quality, reliability and technical excellence.

Our team of experts are happy to assist you in selecting the appropriate products and developing individual solutions for your requirements.