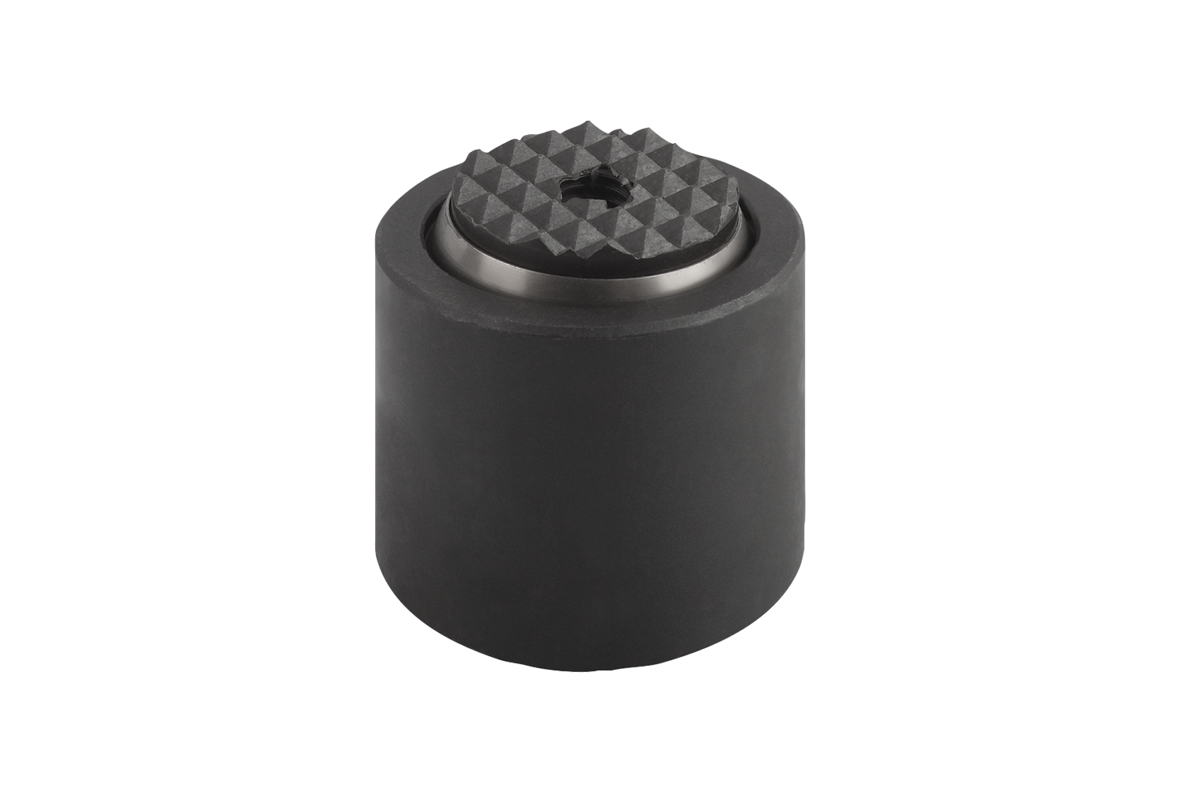

{"product":{"productId":"agid.2239","price":61.3,"name":"Self-aligning pads with O-ring and exchangeable inserts"},"currency":"EUR"}

Material

Body carbon steel.

Ball rust and acid resistant steel.

Inserts:

Form C, F, M tool steel

Form K POM

Form E stainless steel.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane surface.

Ball rust and acid resistant steel.

Inserts:

Form C, F, M tool steel

Form K POM

Form E stainless steel.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane surface.

Version

Body tempered, black oxidised.

Ball hardened, bright.

Inserts:

Form C, F hardened, black oxidised.

Form M with carbide serrations, black oxidised.

Form K white.

Form E hardened, bright.

Form O diamond impregnated surface comparable to 100 grade abrasive grit.

Form P polyurethane surface, hardness 60 Shore.

Ball hardened, bright.

Inserts:

Form C, F hardened, black oxidised.

Form M with carbide serrations, black oxidised.

Form K white.

Form E hardened, bright.

Form O diamond impregnated surface comparable to 100 grade abrasive grit.

Form P polyurethane surface, hardness 60 Shore.

Show more

Show less

Self-aligning pads with O-ring and exchangeable inserts, Form C, flattened steel insert smooth

from

€61.75

plus sales tax

plus shipping costs

Self-aligning pads with O-ring and exchangeable inserts, Form E, flattened stainless steel insert smooth

from

€61.94

plus sales tax

plus shipping costs

Self-aligning pads with O-ring and exchangeable inserts, Form F, flattened ball with diamond grip

from

€70.80

plus sales tax

plus shipping costs

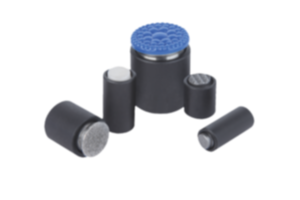

Self-aligning pads with O-ring and exchangeable inserts, Form K, flattened POM insert smooth

from

€61.30

plus sales tax

plus shipping costs

Self-aligning pads with O-ring and exchangeable inserts, Form M, flattened ball with carbide diamond grip

from

€71.03

plus sales tax

plus shipping costs

Self-aligning pads with O-ring and exchangeable inserts, Form O, stainless steel insert with diamond impregnated face

from

€64.97

plus sales tax

plus shipping costs

Self-aligning pads with O-ring and exchangeable inserts, Form P, stainless steel insert with polythene face

from

€64.71

plus sales tax

plus shipping costs

Description

Material

Body carbon steel.

Ball rust and acid resistant steel.

Inserts:

Form C, F, M tool steel

Form K POM

Form E stainless steel.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane surface.

Ball rust and acid resistant steel.

Inserts:

Form C, F, M tool steel

Form K POM

Form E stainless steel.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane surface.

Version

Body tempered, black oxidised.

Ball hardened, bright.

Inserts:

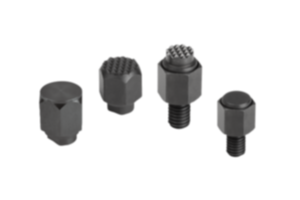

Form C, F hardened, black oxidised.

Form M with carbide serrations, black oxidised.

Form K white.

Form E hardened, bright.

Form O diamond impregnated surface comparable to 100 grade abrasive grit.

Form P polyurethane surface, hardness 60 Shore.

Ball hardened, bright.

Inserts:

Form C, F hardened, black oxidised.

Form M with carbide serrations, black oxidised.

Form K white.

Form E hardened, bright.

Form O diamond impregnated surface comparable to 100 grade abrasive grit.

Form P polyurethane surface, hardness 60 Shore.

Note

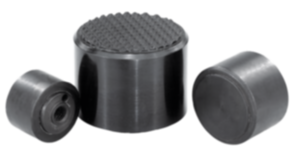

Self-aligning pads are used to support and clamp unmachined and machined workpieces.

In addition, they serve as stops, supports and thrust pads in fixtures and toolmaking.

The ball can be removed from the housing by applying light pressure to the socket head screw.

Ball secured against rotation.

In addition, they serve as stops, supports and thrust pads in fixtures and toolmaking.

The ball can be removed from the housing by applying light pressure to the socket head screw.

Ball secured against rotation.

Advantages

Highly cost-effective as inserts can be exchanged.

The built-in O-ring holds the ball in place and keeps dirt and foreign particles out, ensuring uniform movement.

The built-in O-ring holds the ball in place and keeps dirt and foreign particles out, ensuring uniform movement.

Drawing reference

Form C: flattened steel insert, smooth

Form E: flattened stainless steel insert, smooth

Form F: gripper face

Form K: flattened POM insert, smooth

Form M: gripper face, with carbide serrations

Form O: stainless steel insert diamond impregnated

Form P: stainless steel insert with polyurethane surface

Form E: flattened stainless steel insert, smooth

Form F: gripper face

Form K: flattened POM insert, smooth

Form M: gripper face, with carbide serrations

Form O: stainless steel insert diamond impregnated

Form P: stainless steel insert with polyurethane surface