Spannhaken, Kraftspanner

Spannhaken zeichnen sich durch ihren flexiblen Einsatzbereich und ihren geringen Platzbedarf aus. Sie werden unter anderem im Maschinen-, Werkzeug- und Vorrichtungsbau eingesetzt.

Hook clamps and power clamps from norelem

Reliable holding devices such as hook clamps and power clamps are of crucial importance in industrial production. The standard parts play a key role in fixating the workpiece. The fixating enables precise processing and assembly of various components.

Use of hook clamps and power clamps not only minimises setup times, but also increases production efficiency. Its use ensures precise positioning of the workpieces, resulting in high-quality and consistent end products. In addition, these holding devices contribute to safety in the workplace by fastening workpieces securely and thus minimising the risk of accidents during the machining process.

The versatility of both standard parts allows them to be used in various industries, from metalworking to woodworking. While hook clamps are often operated manually or by simple mechanical mechanisms, power clamps are characterised by their ability to apply a higher clamping force, often through hydraulic or pneumatic systems.

At norelem, we offer high-quality solutions for these requirements to help you optimize your manufacturing processes and achieve precise results.

What are hook clamps?

How does a hook clamp work?

Application areas and functions of the hook clamps

What are power clamps?

Versions of hook clamps and power clamps

Hook clamps and power clamps from the norelem range

What are hook clamps?

A hook clamp is a standard part used in the manufacturing and processing industry. It is used to securely fasten and clamp workpieces. Depending on the specific requirements of the application, they come in different forms and sizes.

The basic function of a hook clamp is to hold the workpiece firmly in place to enable precise processing or assembly. Typically, they are activated by manual operation or mechanical devices to securely fasten the workpiece. This makes it possible to prevent unwanted movements during the machining process and ensure high precision in the manufacture of products.

They are used in various industries, including metalworking and woodworking, plastics processing and general manufacturing. Their versatility and adaptability make them important tools in the manufacturing industry.

How does a hook clamp work?

The exact operating principle of a hook clamp can vary depending on the design and type of standard part. In general, it is used to securely fasten a workpiece and keep it stable during a machining process. In general, hook clamps work as follows:

Firstly, the workpiece to be processed is placed in the desired position.

Then the hook is opened. This can be done either by manual operation or by a mechanism operated through an external force.

By closing the hook, the workpiece is firmly enclosed and held securely. The workpiece is now clamped.

The workpiece can be processed while the hook clamp exerts pressure on it. After processing, the lever can be released and the workpiece removed.

Application areas and functions of the hook clamps

The areas of application for hook clamps are just as diverse as the industry itself. From metalworking to woodworking, they enable precise fixating, regardless of the material. They can be found in the following industrial sectors and applications:

- Plastic processing

- Various installation processes

- Machine tools

- Prototype construction

How a hook clamp works is clear to see.

- Fixating workpieces

- Increase in efficiency

- Precise positioning

- Safeguarding the machining processes

What are power clamps?

A power clamp is used to fasten workpieces quickly and powerfully. Power clamps are specially designed to apply a high clamping force and thus ensure that workpieces are fixated securely during various machining or assembly processes.

The operating principle of a power clamp is often based on hydraulic, pneumatic or mechanical mechanisms. The standard part has a mechanism that makes it possible to increase the clamping force quickly and efficiently, which is particularly important in industrial applications to save time and accelerate production processes. Power clamps are used in various industries, including metalworking, woodworking and assembly processes. They are often integrated on machine tools or special fixtures to hold workpieces securely during the machining process.

Power clamps are therefore indispensable tools for fast and powerful clamping. At norelem, we offer a comprehensive selection of power clamps that combine maximum retaining force with easy handling. Ideal for applications where efficiency and precision have top priority.

Versions of hook clamps and power clamps

Our hook clamps and power clamps not only impress with their quality, but also with their versatility. As at norelem we understand that requirements vary depending on the industry. We therefore offer a wide range of hook clamps that are characterised by precision, reliability and innovation.

Power clamps

The norelem range contains two different types of power clamps.

Accessories used in conjunction with power clamps in industrial manufacturing to improve the versatility and adaptability of these fixtures are:

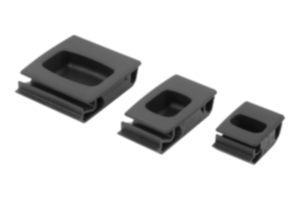

- Thrust pads for power clamps: Are placed on the contact surface of the power clamp. They are used to transfer the force evenly to the workpiece and avoid pressure points.

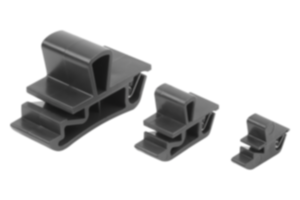

- Raiser for power clamps: Used to increase the clamping height of the power clamp. They are mounted on the base body of the power clamp to enable a larger clamping width.

Riser cylinders and riser blocks

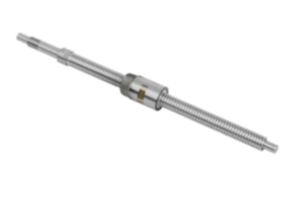

Riser blocks with draw bolt are standard parts that are used in the metalworking and manufacturing industries. A riser block is a type of support or base that is used to lift and stabilise workpieces to a certain height. Draw bolts are a component of the fastening system. A draw bolt is usually defined as a screw with a thread and a drawing device at one end.

The combination of riser blocks and draw bolts makes it possible to lift workpieces to a precisely defined height and hold them securely. This is particularly important in processing steps where precise height positioning of the workpieces is required. Draw bolts can be used to secure the fixed position of the workpieces by passing them through pre-drilled holes in the workpieces and then clamping them.

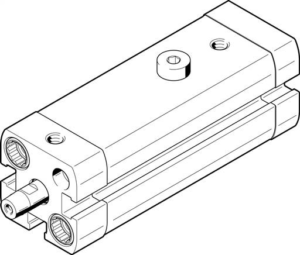

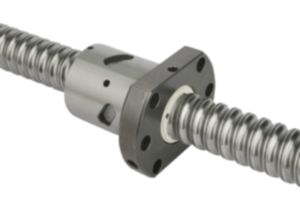

A riser cylinder is a pneumatic or hydraulic part used in industrial manufacturing. It can also be referred to as a lift cylinder or elevator cylinder. The riser cylinder consists of a cylindrical housing containing a piston that can expand or contract under pressure.

Riser cylinders are often used in automated production systems to move workpieces to the correct height so that they can move on to the next processing step. The cylinder is able to perform precise lifting movements. It therefore contributes to the automation and increased efficiency of manufacturing processes.

Hook clamps

The hook clamp product family includes a range of different hook clamps as well as hook clamp holders.

A hook clamp holder is a fixture that safely and efficiently integrates hook clamps into machine tools or production equipment. The mount plays an important role in ensuring precise fixating and handling of the hook clamps.

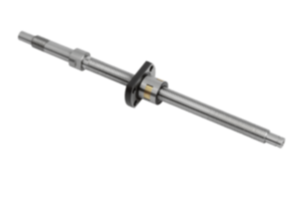

One hook clamp that is particularly worth highlighting is the clamp hook with collar.

The collar allows the hook clamp to be swivelled by up to 90°. This function makes it much easier to insert and remove workpieces. Precise adjustment of the clamping height is effortless with the fine thread on the stud, which can be easily operated using a screwdriver. For additional safety, the setting can be fixed using the locking screw.

Here you can see the hook clamp with collar in an application video.

Other clamps in the range include:

Hook clamps and power clamps from the norelem range

With our wide range of hook clamps and power clamps, you can be sure to find the ideal solution for your requirements. Quality is our top priority. Our hook clamps and power clamps undergo strict quality controls to meet the highest standards. Rely on durable and reliable holding devices that meet the requirements of your manufacturing processes.

Trust norelem to take your manufacturing processes to the next level.

Do you have any questions or need additional information?