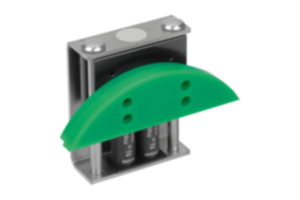

{"product":{"productId":"agid.34357","price":130.69,"name":"Chain tensioner size 1 with arched profile"},"currency":"EUR"}

Material

Outer housing and C-profile steel.

Inner housing plastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Springs stainless steel.

Inner housing plastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Springs stainless steel.

Version

Outer housing and C-profile electro zinc-plated and painted black.

Show more

Show less

Chain tensioner size 1 with arched profile, Form A

from

€130.69

plus sales tax

plus shipping costs

Chain tensioner size 1 with arched profile, Form B

from

€152.59

plus sales tax

plus shipping costs

Description

Material

Outer housing and C-profile steel.

Inner housing plastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Springs stainless steel.

Inner housing plastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Springs stainless steel.

Version

Outer housing and C-profile electro zinc-plated and painted black.

Note

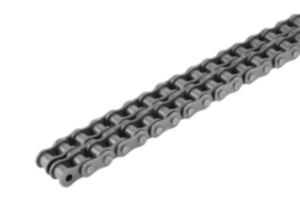

Ready-to-install chain tensioner for low-noise, low-wear operation of ISO 606 roller chains. The robust steel housing offers high durability and reliable operation.

Available with two tensioning forces and two models:

Light spring force version: 174 - 32 N.

Strong spring force version: 396 - 60 N.

Form A: Short housing.

Form B: Long housing.

For applications with frequent direction changes, we recommend the chain tensioner with the long housing. We supply these exclusively with strong spring force.

Simple wear control with the three-colour wear indicator

green: ok

yellow: still ok

red: insufficient spring travel. The chain tensioner needs to be readjusted. The chain must be replaced when the range of all adjustment options no longer ensures sufficient readjustment.

Available with two tensioning forces and two models:

Light spring force version: 174 - 32 N.

Strong spring force version: 396 - 60 N.

Form A: Short housing.

Form B: Long housing.

For applications with frequent direction changes, we recommend the chain tensioner with the long housing. We supply these exclusively with strong spring force.

Simple wear control with the three-colour wear indicator

green: ok

yellow: still ok

red: insufficient spring travel. The chain tensioner needs to be readjusted. The chain must be replaced when the range of all adjustment options no longer ensures sufficient readjustment.

Temperature range

-20 °C to +60 °C (briefly up to +80 °C).

Assembly

The ideal mounting location is directly behind the drive sprocket, so that the length of the slack side being tensioned is kept as short as possible. Several chain links should be in contact to minimise wear.

The size 1 chain tensioner is supplied in a locked state. Only after installation are the locking screws on the springs of the clamping core released. The middle of the three locking screws is loosened with approx. four turns. The other two springs are only released if required.

The size 1 chain tensioner is supplied in a locked state. Only after installation are the locking screws on the springs of the clamping core released. The middle of the three locking screws is loosened with approx. four turns. The other two springs are only released if required.

Accessory

Angle brackets 22281-90.