norelem measures – 32000

The norelem product group 32000 consists of two categories:

- Concentricity gauges

- Dial gauges

All about concentricity gauges

A concentricity gauge is a measuring device used in the manufacturing industry. The inspection equipment is used to check the concentric accuracy of cylindrical components. Concentricity gauges are frequently used in the manufacture of cylindrical components for precision machines, tools and other equipment.

A concentricity gauge consists of a rotating shaft to which the component to be tested is attached. The shaft is able to reach a high speed in order to simulate the exact rotation of the component. Sensors are fitted at various positions along the shaft to detect and measure the concentricity of the component.

The concentricity test is carried out to check the accuracy of machine parts. At the start of the test procedure, the component to be tested is attached to the shaft and the machine is switched on. While the component is set in a rotary motion, i.e. rotates, the dial gauge holder and dial gauge continuously take measurements.

The results can be used to determine whether the component runs smoothly or whether there are deviations in form or alignment. If the concentricity gauge detects a deviation from the ideal concentricity, appropriate corrective measures can be taken to optimise the component or adapt the production process.

The concentric accuracy of a component therefore indicates how precisely and evenly it rotates around its own axis. High concentric accuracy is particularly important for applications where minimal vibration, noise or imbalance is required. Examples include high-quality precision machines, tools for metalworking and optical components.

Concentricity gauges at norelem

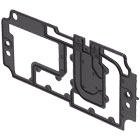

The norelem range includes two types of concentricity gauges. Both measuring tools are suitable for measuring concentricity, run-out and perpendicularity. The measuring workpiece is easy to position as the contact roller can be lifted off. The force of the contact roller is also adjustable. The dial gauge can be positioned as required using the slide.

- The concentricity gauge for diameters up to 35 mm has an average test range of 5 mm to 35 mm.

- The concentricity gauge for diameters up to 80 mm has an average test range of 5 mm to 80 mm. The roller spacing is a minimum of 29 mm to a maximum of 89 mm.

You will find suitable accessories for the concentricity gauge here .

Dial gauges

Dial gauges are widely used measuring instruments that are used in various industries and applications to perform precision measurements. They are specially designed to measure small linear deviations or distances.

Versions of a dial gauge

There are different types of dial gauges, including digital dial gauges and dial gauges acc. to DIN 878. Both types of dial gauges have their advantages and disadvantages.

Dial gauge DIN 878

Dial gauges acc. to DIN 878 are manufactured in accordance with German industry standards. This standard defines certain requirements and specifications for dial gauges to ensure that they are highly accurate and reliable. Dial gauges acc. to DIN 878 are characterised by their robust design, precision mechanics and compliance with specific tolerance values. They are particularly popular in industries such as metalworking, tool manufacturing and precision laboratories.

The DIN 878 dial gauge from norelem has a robust, chromed metal housing. The measuring range is 10 mm with a scale graduation of 0.01 mm.

Dial gauges acc. to DIN 878 are known for their robust design and durability. They are less susceptible to damage from external influences and can also be used in challenging environments. However, they may require a little more experience and skill when interpreting the measured values on the analogue scale.

Digital dial indicator

The digital dial gauge is a modern version of the dial gauge. It uses electronic technology to read measurements precisely and easily. The digital dial gauge has a digital display on which the measured values are shown directly. Digital dial gauges generally offer a higher resolution and accuracy than conventional analogue dial gauges.

They also enable functions such as data recording, storage of measured values and the setting of tolerance limits. The digital dial gauge from norelem has a hardened and ground measuring spindle. The dial gauge's reading field can be rotated through 280°. The measuring system can be switched from mm to inches.

Digital dial gauges offer easy reading, additional functions and high accuracy. They are also more user-friendly and require less manual interpretation of the measured values. On the other hand, they can be more sensitive to harsh environmental conditions and soiling.

In addition to the two types of dial gauges, the category also includes "Dial gauges" and replacement batteries for the digital dial gauge.