{"product":{"productId":"agid.35219","price":299.44,"name":"Floating clamps, steel"},"currency":"EUR"}

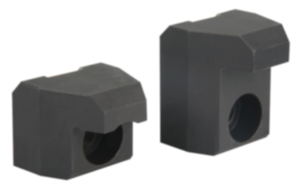

Material

Body and jaw steel.

Limit stop aluminium.

Limit stop aluminium.

Version

Body black oxidised.

Jaws nitrocarburised and black oxidised.

Limit stop black anodised.

Jaws nitrocarburised and black oxidised.

Limit stop black anodised.

Show more

Show less

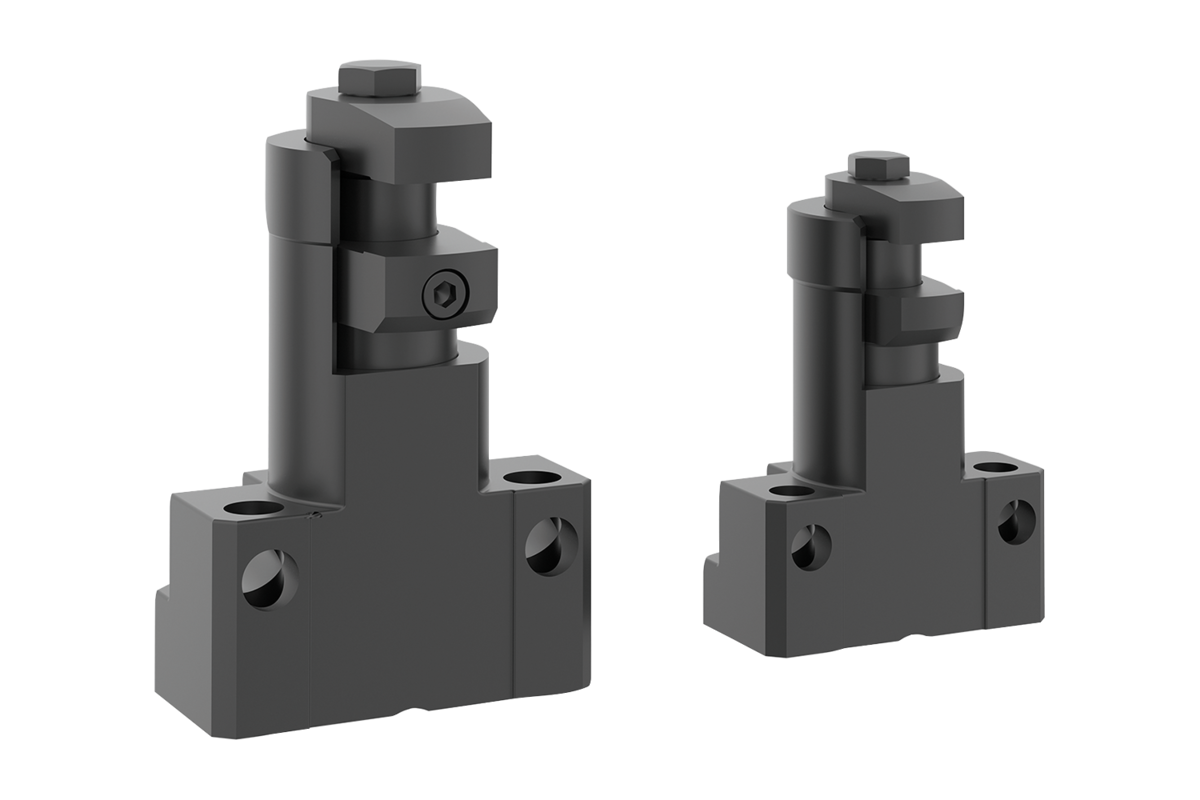

Floating clamp, steel Form A

from

€299.44

plus sales tax

plus shipping costs

Floating clamp, steel Form B

from

€466.00

plus sales tax

plus shipping costs

Description

Material

Body and jaw steel.

Limit stop aluminium.

Limit stop aluminium.

Version

Body black oxidised.

Jaws nitrocarburised and black oxidised.

Limit stop black anodised.

Jaws nitrocarburised and black oxidised.

Limit stop black anodised.

Note

The floating clamp is used to clamp and support overhanging clamping points on components. It prevents vibrations and deflection during machining.

Method of operation

1. Push the floating clamp down.

2. Pivot the jaws up to the stop. Now the floating jaw of the floating clamp should rest against the underside of the workpiece.

3. Tighten the floating clamp with the hex nut (observe the min. and max. tightening torque). During clamping, the workpiece is clamped and simultaneously supported.

4. To release, perform the procedure in reverse order.

2. Pivot the jaws up to the stop. Now the floating jaw of the floating clamp should rest against the underside of the workpiece.

3. Tighten the floating clamp with the hex nut (observe the min. and max. tightening torque). During clamping, the workpiece is clamped and simultaneously supported.

4. To release, perform the procedure in reverse order.

Assembly

Set the height range and the pivot range, then attach the floating clamp to the bracket using the holes (D1).

When setting the height, a generous allowance above should be taken into account.

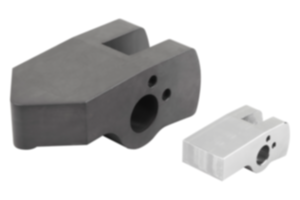

Form B:

For special clamping applications, the standard clamping jaw can be modified or replaced.

When setting the height, a generous allowance above should be taken into account.

Form B:

For special clamping applications, the standard clamping jaw can be modified or replaced.

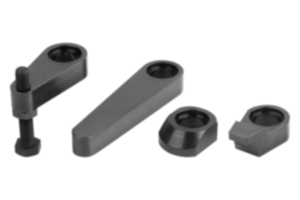

Drawing reference

1) Exchangeable jaw

2) M6 ISO 4762 cap screw

3) Fastening point for clamping jaw

2) M6 ISO 4762 cap screw

3) Fastening point for clamping jaw