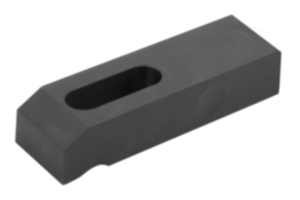

Material

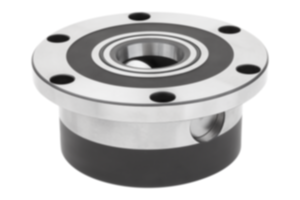

Carbon steel.

Version

Contact faces hardened and ground.

Show more

Show less

Description

Material

Carbon steel.

Version

Contact faces hardened and ground.

Note

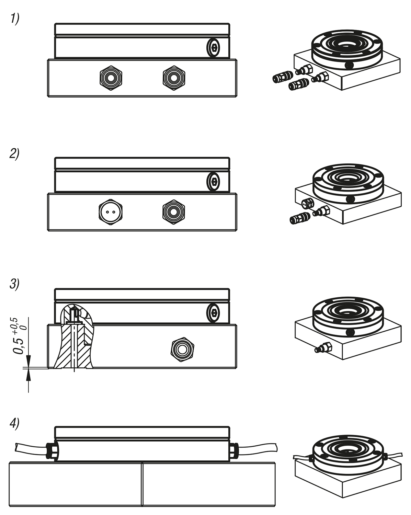

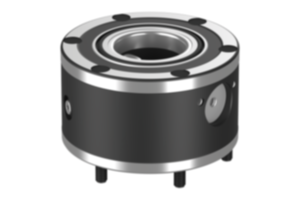

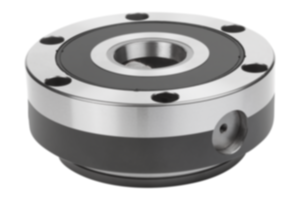

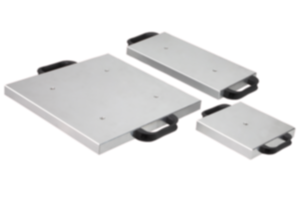

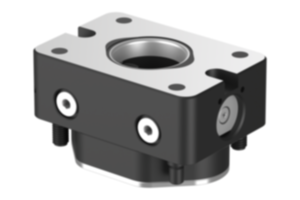

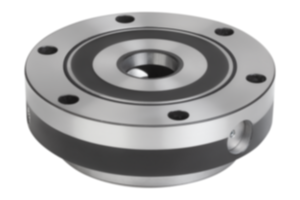

The UNILOCK clamp modules can be mounted in any position, with or without projection on machine tables or as part of fixtures (plates, cubes, towers etc). The pneumatic control of the clamping modules can be carried out independently or together,thus an individual zero-point clamping system can be fabricated.The modular design allows the number of and distance between the clamp modules to be ideally adjusted to suit the clamping task. The set-up times are significantly reduced and so the running times of the machines are extended.

A very low installation height of the clamping modules is achieved by the compact design of the flat clamping slides.

The high clamping forces are generated by the integrated spring package (the unit is clamped without constant air pressure).

The release process is pneumatic.

Even in the event of a pressure drop or fluctuations in the compressed air supply, the full traction force is maintained.

All clamping modules have a turbo function included as standard. A short air impulse at the ”Turbo” air port increases the normal traction force, achieved by the springs, significantly. Consequently, the clamping modules can also be used for heavy-feed machining.

Use of the turbo function for maximum traction force is recommended.

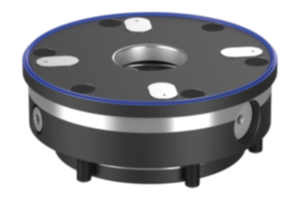

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Clamping force with DIN EN ISO 4762 -12.9 cap screws.

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

A consistent clamping bolt size for all clamping modules and compatibility with the 5-axis module clamping system 80 guarantees diverse combinations of application possibilities.

The ERGO clamping modules are available with and without rotation lock.

A very low installation height of the clamping modules is achieved by the compact design of the flat clamping slides.

The high clamping forces are generated by the integrated spring package (the unit is clamped without constant air pressure).

The release process is pneumatic.

Even in the event of a pressure drop or fluctuations in the compressed air supply, the full traction force is maintained.

All clamping modules have a turbo function included as standard. A short air impulse at the ”Turbo” air port increases the normal traction force, achieved by the springs, significantly. Consequently, the clamping modules can also be used for heavy-feed machining.

Use of the turbo function for maximum traction force is recommended.

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Clamping force with DIN EN ISO 4762 -12.9 cap screws.

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

A consistent clamping bolt size for all clamping modules and compatibility with the 5-axis module clamping system 80 guarantees diverse combinations of application possibilities.

The ERGO clamping modules are available with and without rotation lock.

Technical Data

- Traction force with turbo from 18 kN.

- System pressure: 6 bar, lubricated air.

- Repeat accuracy ≤0.005 mm.

- Temperature range 5° to 60° C.

- Optional port for blow-out air.

- System pressure: 6 bar, lubricated air.

- Repeat accuracy ≤0.005 mm.

- Temperature range 5° to 60° C.

- Optional port for blow-out air.

Advantages

- Compact flat design through flat slides.

- Turbo-function as standard.

- Repeat accuracy ≤0.005 mm.

- Positioning via short taper.

- High traction force.

- Setup time optimisation.

- Turbo-function as standard.

- Repeat accuracy ≤0.005 mm.

- Positioning via short taper.

- High traction force.

- Setup time optimisation.

Scope of delivery

1x clamping module.

1x O-ring Ø95x1,5.

2x O-rings Ø8x2 for media feed.

6x fastening screws.

6x cover caps for fastening screws.

1x O-ring Ø95x1,5.

2x O-rings Ø8x2 for media feed.

6x fastening screws.

6x cover caps for fastening screws.

Attention

Recommended nominal hose size:

- Up to four clamping modules, hose size 6 mm.

- From five clamping modules, hose size 8 mm.

- Up to four clamping modules, hose size 6 mm.

- From five clamping modules, hose size 8 mm.

Drawing reference

1) O-ring (Ø8x2)

2) O-ring (Ø110x1.2)

2) O-ring (Ø110x1.2)

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.